Manufacturing Display

Continuously optimize manufacturing equipment, improve the production capacity of intelligent equipment, and gradually reduce production costs!

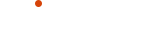

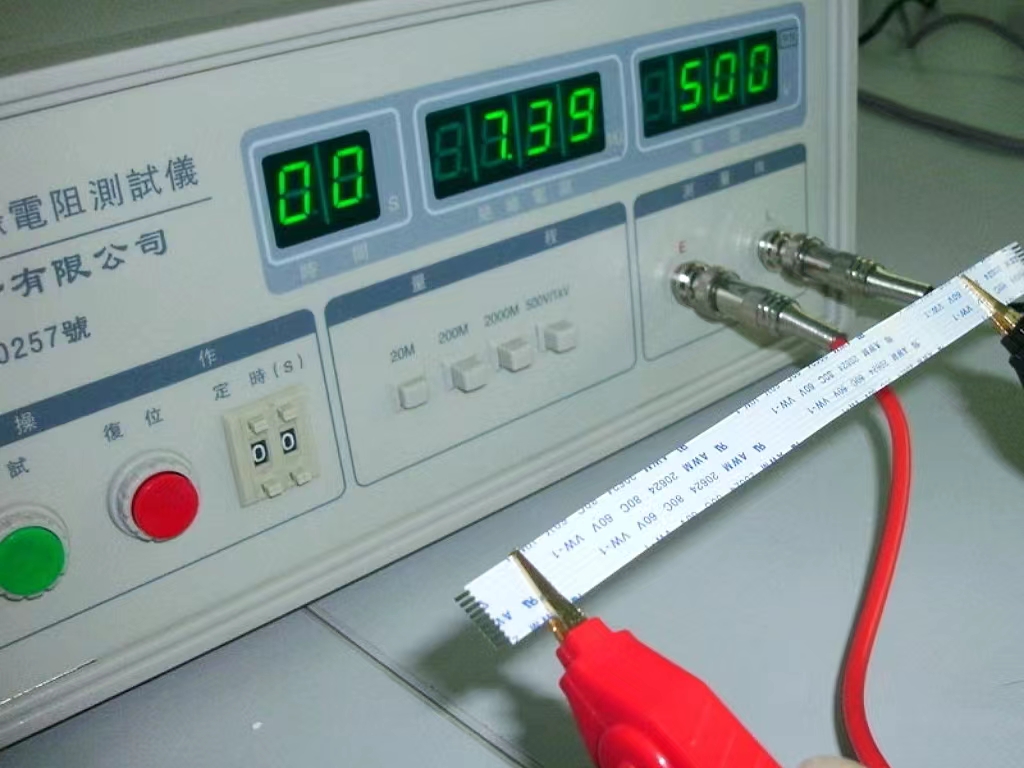

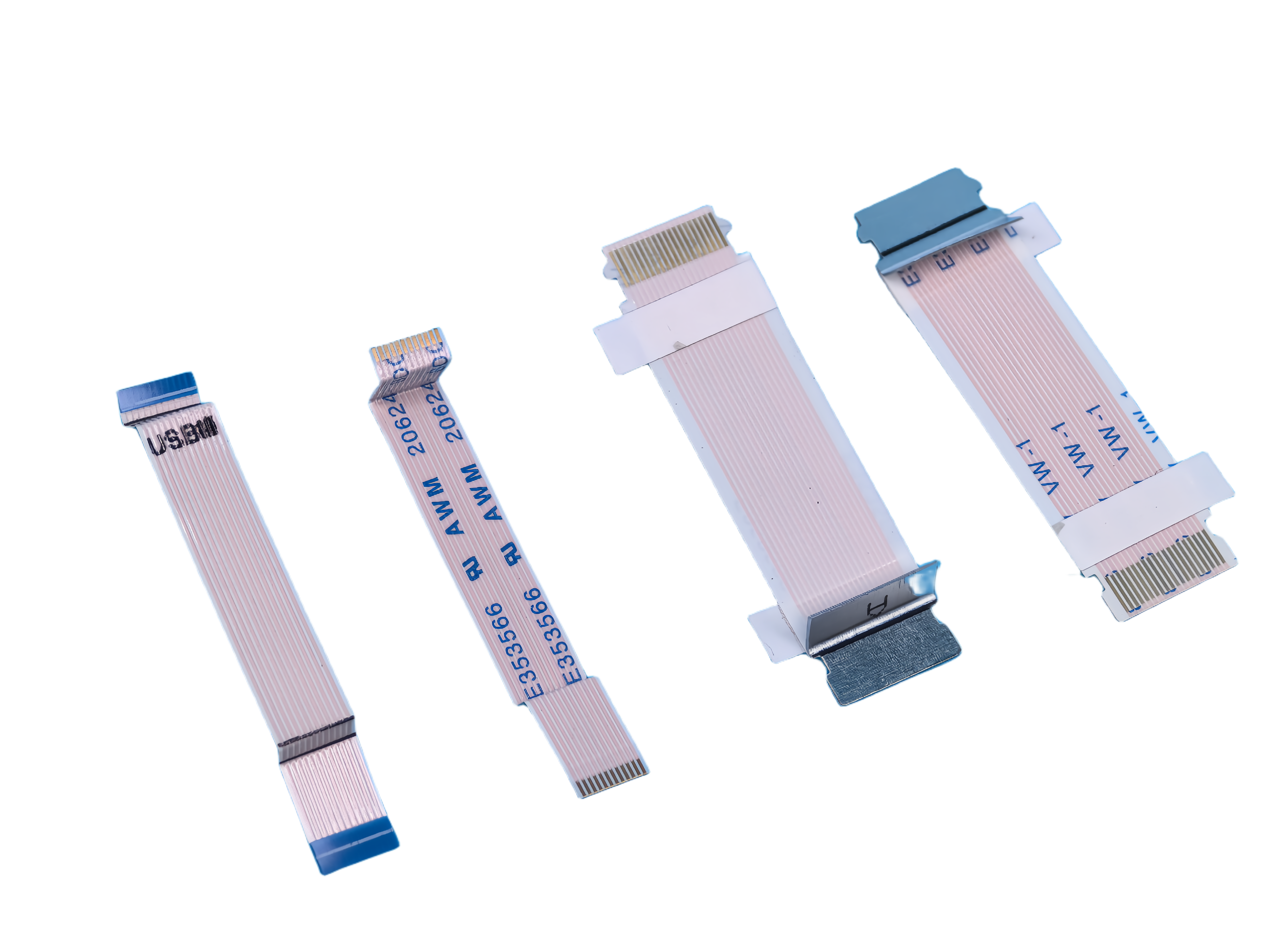

1.FFC Series: XinLinJin has realized the whole process of automated self-manufacturing for FFC products with the core techniques including wire merging - slitting - pasting shielding materials - folding - testing. Now, XinLinJin has adopted the use of automatic equipment manufacturing, and has been equipped with fully-automatic forming machine, slitting machine, glue dispenser, punching machine, laser machine, inkjet printer, folding machine, and so on. Outsourcing raw materials: copper wire and insulation materials.

2. Harness+Cable Series: XinLinJin has realized the whole process of automated self-manufacturing techniques: cutting wire - riveting terminals - inserting terminals - post-processing. Its wiring harness production line now has been equipped with automatic equipment including fully-automatic double-head terminal machine, five-wire terminal machine, automatic wire feeder and pricking terminal machine. Outsourcing materials: copper wires and terminal housing.

3. MCC Coaxial Cable Series: XinLinJin has mastered the whole process of self-manufacturing techniques for coaxial cable: wire arranging-cutting-stripping-tinning-soldering-UV glue curing-post processing. At present, its coaxial cable production line has been equipped with automatic facilities like HOT BAR pulse welder, laser machine, tinning machine, single/double side pulse welder, soldering pointing machine, UV glue curing machine. Outsourcing materials include the extremely fine coaxial cable and EDP&LVDS connectors.

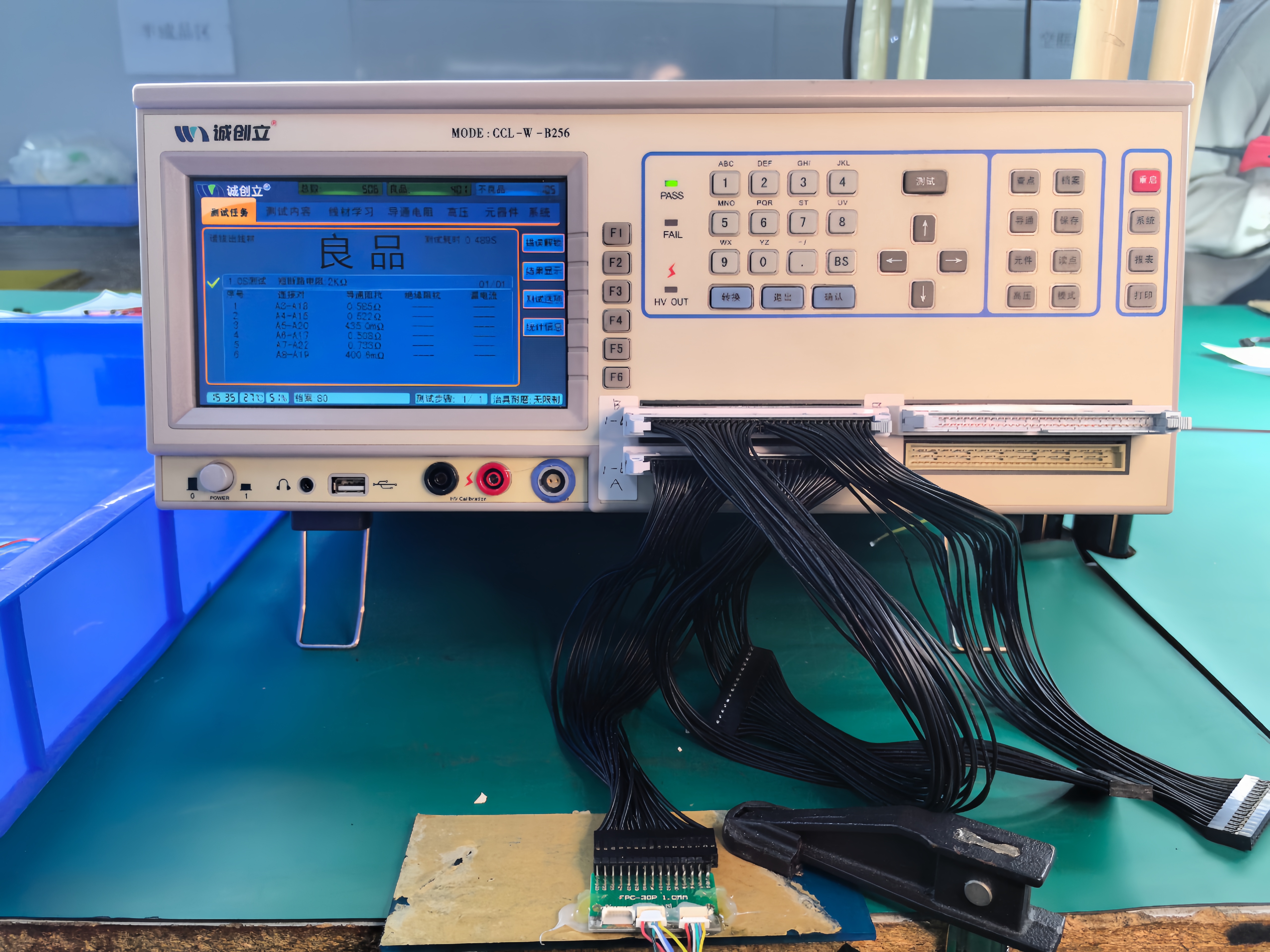

Product Reliability Guarantee (PRG)

Since its inception, XinLinJin team consists of partners from large-scale factories with Taiwanese and Japanese backgrounds. They are of mature management experience and standardized operational skills in designing, manufacturing and testing. We have strict verification standards and testing methods for our products in terms of the function, operating environment, and environmental friendliness. We strictly control the quality of raw materials in our factories and combine internal testing with external third-party verification to provide our customers with a reliable supply of wiring harness components.

Certificates

XinLinJin fully implements the ISO9001-2015 international quality management system standards, strictly adheres to UL safety regulations of the United States and the certification standards of IATF16949 automotive quality management system, with a view to guarantee a higher quality and further provide a more market-competitive product offering on the basis of synchronizing and collaborating with our customers' demands.

Engineering Customized Design

Thanks to more than 10 odd years of product manufacturing, we have accumulated much producing experience in TV display signal transmission and in-vehicle product manufacturing. For example, in the area of FFC+LVDS, HARNESS+LVDS, MIPI EDP, etc., we have cooperated with and assisted many customers in solving difficulties like weak signal attenuation, shielding, and pressure drop of long wiring harnesses for commercial displays; and in the area of in-vehicle cables, we have also cooperated with some well-known car manufacturers and solved the safety problems of related products being used in specific circumstance.

Development History

2011: Officially Established was ShenZhen TianDeLi Electronics Co.,LTD;

2012: FFC series passed the UL Safety Regulations of the United States;

2013: Applied for and obtained the ISO9001 Quality System Certification;

2014: Cooperated with excellent enterprises in home and abroad, such as Liyan, Laier and Sanling;

2015: Gotten contact and Cooperated with Japan materials suppliers, providing customers with first-class products;

2018: FFC series of TianDeLi being taken over by ShenZhen XinLinJin Electronics Technology CO., LTD;

2019: XinLinJin applied for and obtained a patent on its FFC+EDP series products.

2022:The factory has passed IATF16949 automotive quality management system certification.

Corporate Culture

Corporate Mission: Devoting strength to the world’s common connection

Corporate Vision: Be a value-added partner to customers and provide a growth platform for employees

value system: integrity respect foresight struggle sharing gratitude

Corporate Spirit: To be a leading provider for connection cable

Work Style: quick response;immediate action